KST – KROMSCHRÖDER SYSTEM TECHNOLOGY

Air min. air pressure monitor (SIL 2, PL d)

The Air min. air pressure monitor described in EN 746-2:2010 subclause 5.2.2.5.1 is designed to monitor the combustion air supply during the pre-purge, the burner start and the burner operation of the system. If the level falls below the set limit value, the system must perform a fault lock-out.

The air pressure monitor must be checked prior to system start-up to establish its “no flow” state. In the event of an error during the “no flow” state check, system start-up must be prevented.

Risk

CO formation due to excess gas → explosion

Determining the required SIL pursuant to IEC 62061

Frequency & exposure duration Fr: < 1 per h to ≥ 1 per day; > 10 min → 5 points

Probability Pr: thanks to the downstream air deficiency cut-out on each burner (pneumatic ratio control system, pressure switch), the probability that a hazardous event occurs is rather low. → 2 points

Avoidance Av: the hazard can be avoided by regular maintenance and by checking the pressure switch for contact changeover pursuant to EN 746-2. → 3 points

Effects: death, loss of an eye or arm

Determining the required PL pursuant to ISO 13849-1

Severity of injury S: severe (usually irreversible injury including death) → S2

Frequency and/or duration of hazard exposure F: frequent to continuous and/or long exposure to hazard → F2

Possibility of avoiding hazard or limiting harm P: possible under certain conditions → P1

Enter details

Enter the calculated values in the adjacent “app” to determine the required safety level.

App: Determining the required SIL, PL

Select products

The required SIL and PL can be achieved with these products. The calculation (see below) provides verification of this.

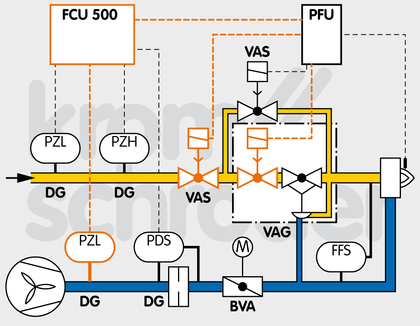

Sensor: pressure switch for gas DG

Logic: protective system control FCU

Actuator: solenoid valves for gas VAS

Application

The flowchart shows how the products are integrated into the application to achieve the required safely level.