KST – KROMSCHRÖDER SYSTEM TECHNOLOGY

High temperature monitoring (SIL 3, PL e)

The high temperature limit monitoring described in EN 746-2:2010 subclause 5.2.6.3 replaces the flame control for the burners in operating phases in which ionization/UV flame control is no longer possible.

The limit monitoring is designed to switch from flame control to temperature monitoring in the automatic burner control unit.

The high temperature limit monitoring has the same safety goal as the flame control in the automatic burner control unit.

Risk

Non-combusted gas in the combustion chamber → explosion

Determining the required SIL pursuant to IEC 62061

Frequency & exposure duration Fr: < 1 per h to ≥ 1 per day; > 10 min → 5 points

Probability Pr: without high temperature monitoring, this event is likely to occur. → 4 points

Avoidance Av: avoiding the hazard is impossible. → 5 points

Effects: death, loss of an eye or arm

Determining the required PL pursuant to ISO 13849-1

Severity of injury S: severe (usually irreversible injury including death) → S2

Frequency and/or duration of hazard exposure F: frequent to continuous and/or long exposure to hazard → F2

Possibility of avoiding hazard or limiting harm P: hardly possible → P2

Enter details

Enter the calculated values in the adjacent “app” to determine the required safety level.

App: Determining the required SIL, PL

Select products

The required SIL and PL can be achieved with these products. The calculation (see below) provides verification of this.

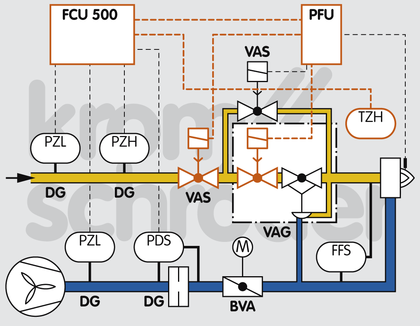

Sensor: protective system control FCU with connected twin thermocouple

Logic: automatic burner control unit PFU

Actuator: solenoid valves for gas VAS

Application

The flowchart shows how the products are integrated into the application to achieve the required safely level.