KST – KROMSCHRÖDER SYSTEM TECHNOLOGY

Air Supply

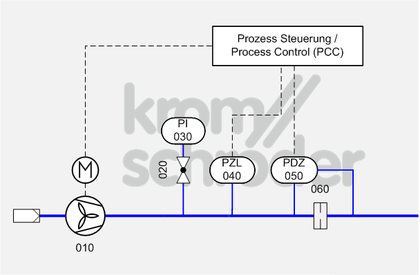

Air supply including fan control

Standard: EN 746-2

| No. | Component description | Standards and Docuthek |

|---|---|---|

| 010 | Combustion air fan with intake filter | |

| 020-030 | Pressure gauge, e.g. pressure gauge with capsule element KFM with pressure gauge valve DH or MH | Docuthek |

| 040 | Air deficiency cut-out, e.g. pressure switch DG | 5.2.2.5.1 Air |

| 050 | Air flow detector, e.g. pressure switch DG as differential pressure switch | 5.2.2.5.1 Air |

| 060 | Air orifice, e.g. Type VMO for air flow monitoring with differential pressure switch | Docuthek |

Application

Central combustion air supply with air deficiency cut-out and air flow monitoring

Function

The supply air pressure generated by the fan (010) is monitored by the pressure switch (040) acting as an air deficiency cut-out. When the fan is started by the process control system, contact changeover at the pressure switch is checked.

During the pre-purge, a differential pressure switch (050) monitors the air flow on the orifice (060).

If there is no air pressure supplied or if there is no differential pressure on the orifice, the system will be blocked.

Notes

- EN 746-2 recommends that the intake filter on the fan be monitored for soiling. This can occur directly through a differential pressure switch on the filter or indirectly through a second air pressure switch on the pressure side of the fan. The filter monitoring pressure switch triggers a warning, however it does not need to be linked into the safety interlocks.

- In many cases it is recommended that the combustion air be taken in from outside the production hall so as to extend the cleaning intervals for the intake filter. However, drawing in air from the outside does not do away with the need for an intake filter.