KST – KROMSCHRÖDER SYSTEM TECHNOLOGY

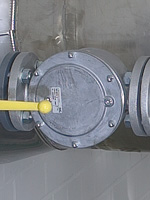

5.2.2.2 Filter/strainer

Special care shall be taken to prevent the ingress of particles, either from the pipework or from the gas, which would be detrimental to the operation of the equipment by the incorporation of a suitable filter or strainer immediately downstream of the first manual isolating valve of the IThE.1) Additional filters/strainers may be required (e.g. immediately upstream of the automatic shut-off valve).The filter and/or the strainer shall be positioned in such a way that periodic servicing remains easy.

In the event of the installation of a by-pass to the filter and/or the strainer, an identical filtering device shall be installed on the by-pass line.

Filter and/or the strainer shall be checked at intervals specified in the instruction handbook.2)

The following chapters are printed with the permission of the DIN Deutsches Institut für Normung e.V. (German Institute for Standardization). For the implementation of the DIN Standard, the version with the most recent issue date is deemed authoritative. This is available from Beuth Verlag GmbH, Burggrafenstrasse 6, 10787 Berlin, Germany.

![]()

Our note on this Standard:

1) The functioning of all controls in a gas or air appliance mostly depends on the quality of the medium. To ensure that the individual controls function properly, a suitable filter or strainer must be installed directly downstream of the first manual shut-off valve. The pore size of the filter pad should be ≤ 50 µm.

In the case of highly contaminated gases, it is also recommended to install a Y-strainer. The mesh size here is 400 µm as standard. The Y-strainer serves a pre-cleaning function and is not intended as a replacement for the gas filter.

2) The degree of soiling of the filter pad can be determined on the basis of the differential pressure.

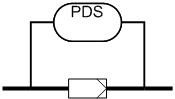

Filter with differential pressure monitoring

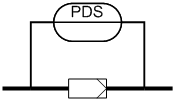

Filter with differential pressure monitoring and signalling to the control system