KST – KROMSCHRÖDER SYSTEM TECHNOLOGY

Gas inlet sections

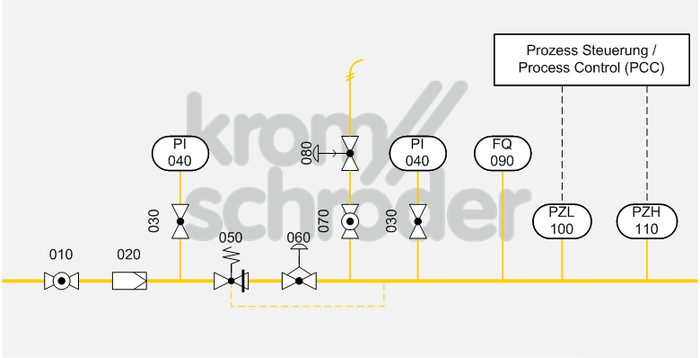

Gas pressure control and measuring train

| No. | Component description | Standards and Docuthek |

|---|---|---|

| 010 | Manual isolating valve, e.g. manual valve AKT | |

| 020 | Filter, e.g. gas filter GFK

|

|

| 030-040 | Pressure gauge, e.g. pressure gauge with capsule element KFM or pressure gauge with Bourdon tube RFM with pressure gauge valve DH or MH | |

| 050 | High pressure shut-off device, e.g. safety shut-off valve JSAV

|

|

| 060 | Gas pressure regulator, e.g. pressure regulator for gas VGBF

|

|

| 070 | Shut-off valve, e.g. manual valve AKT

During operation, the valve must be secured open.

|

|

| 080 | Relief valve, e.g. safety relief valve VSBV

Safety relief valves are designed to relieve pressure peaks in pipe systems thus preventing the safety shut-off valve from being activated unintentionally. |

|

| 090 | Gas metering equipment, e.g. flow meters DM, DE | |

| 100 | Low-pressure cut-off, e.g. pressure switch for gas DG

The min. pressure switch setpoints to be adjusted depend on the installation location and the process conditions.

|

|

| 110 | High gas pressure protection, e.g. pressure switch for gas DG

The max. pressure switch setpoints to be adjusted depend on the installation location and the process conditions.

|

Application

Main gas train to EN 746-2. This is a part of the gas distribution system of the industrial thermoprocessing equipment (IThE), e.g. for downstream multiple burner systems.

Function

If the main shut-off valve (010) is open, the pressure and quantity required for the IThE are controlled by the gas pressure regulator (060). Any dirt in the gas or pipe system will be removed by the filter (020) first. If the gas pressure regulator (060) suffers a fault (e.g. a diaphragm fracture), the gas supply will be stopped safely by the high pressure shut-off device (050). The relief valve (080) prescribed here vents low leakage rates of the high pressure shut-off device and prevents unintentional tripping in the event of pressure surges. It therefore ensures the supply of the IThE is highly reliable.

The low-pressure cut-off (100) and the high gas pressure protection device (110) are part of the protective system. These compulsory safety devices are actuated separately by the process control system. In the case of insufficient or excessively high gas flow, the process control system will receive a signal and shut off the gas supply safely by closing two valves fitted in series. These valves can be part of the downstream burner system.

The quantity of gas consumed can be read off the flow meter (090). The inlet and outlet pressure will be displayed on the pressure gauges (030/040).

Note

The respective unit accuracy groups, lock up pressure classes and accuracy classes must be observed to ensure optimum adjustment of gas pressure regulator, high pressure shut-off device and relief valve. We recommend the generation of a pressure scaling diagram to exclude tolerance-related interferences of settings.